How 3D Scanning Replicated a Century of Weathering on a Nashville Porch

In the historic neighborhoods of Nashville—where the Greek Revival and Italianate porches of Germantown and Belmont-Hillsboro define the streetscape—authenticity is everything.

But here’s the dilemma: if you have a 110-year-old porch with five missing ornamental column tops (capitals), a brand-new, hand-carved replacement often looks too perfect. It stands out like a sore thumb against the five originals and surrounding wood work that have been gracefully weathered by a century of Tennessee humidity and Nashville winters.

We recently tackled this exact problem. Instead of trying to "fake" antiquity, we used Reverse Engineering and Additive Manufacturing to clone the history itself.

The Problem with "New"

Traditional restoration usually involves a master carver recreating the original design. While beautiful, a fresh carving lacks the "softened" edges, wood grain expansion, and subtle wear that give historic homes their character. Our goal was to ensure the five new column tops were indistinguishable from the five originals—down to the last millimeter of age.

The High-Tech Restoration Workflow

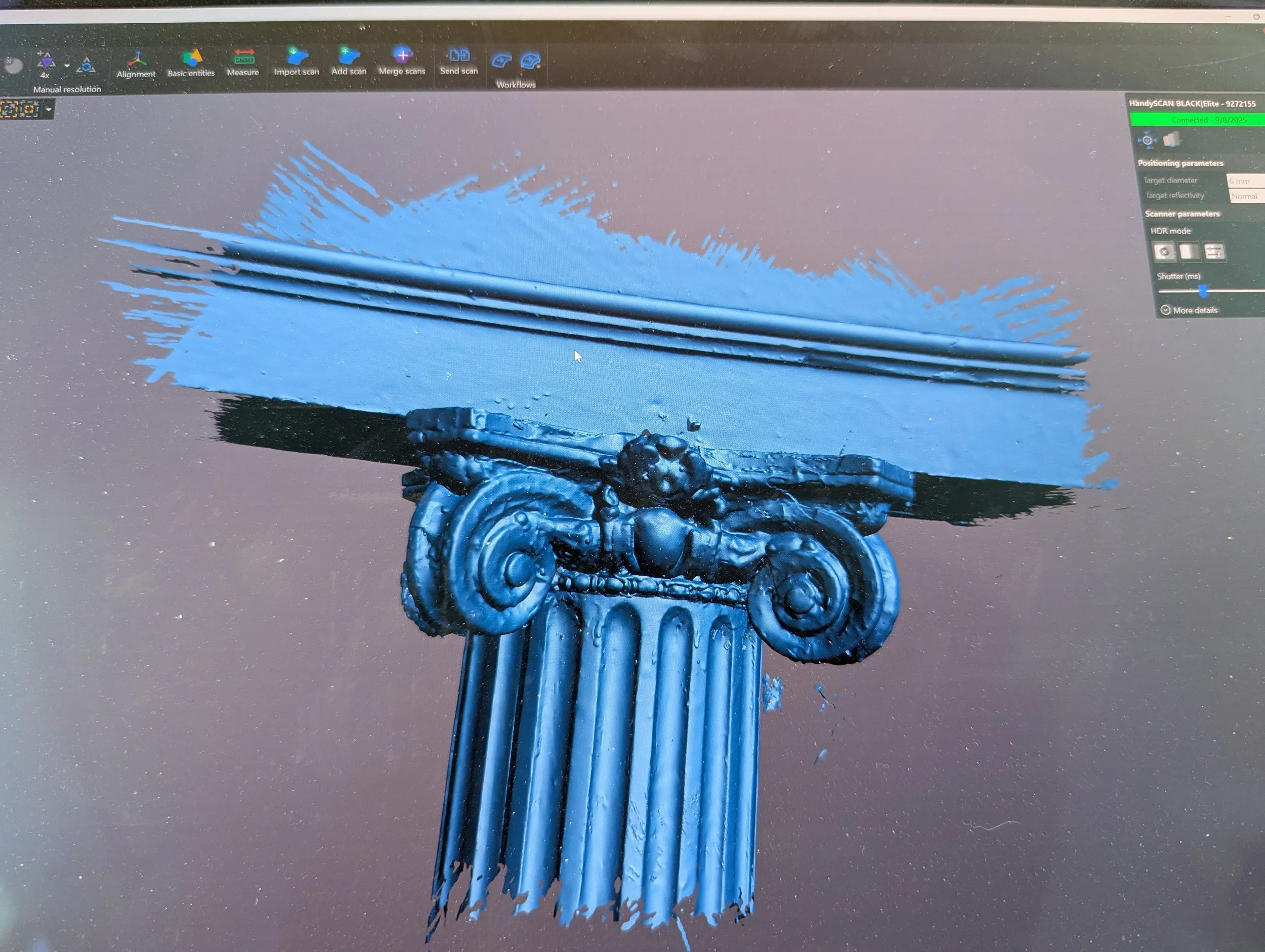

1. Capturing the "DNA" of the Porch

We began by performing a high-resolution Metrology-grade Laser Scan of one of the remaining original capitals. Unlike a photograph, the scan captures a high-density Point Cloud, creating a digital "twin" that includes every crack, dip, and weathered detail earned since the early 1900s.

2. Digital Surgery & CAD Alignment

Once in the digital workspace, we cleaned the data. We oriented the scan to a true vertical axis and used Boolean operations to "subtract" the flat top of the column shaft from the ornamental scan. This ensured the new parts would seat perfectly flush on the existing structural posts.

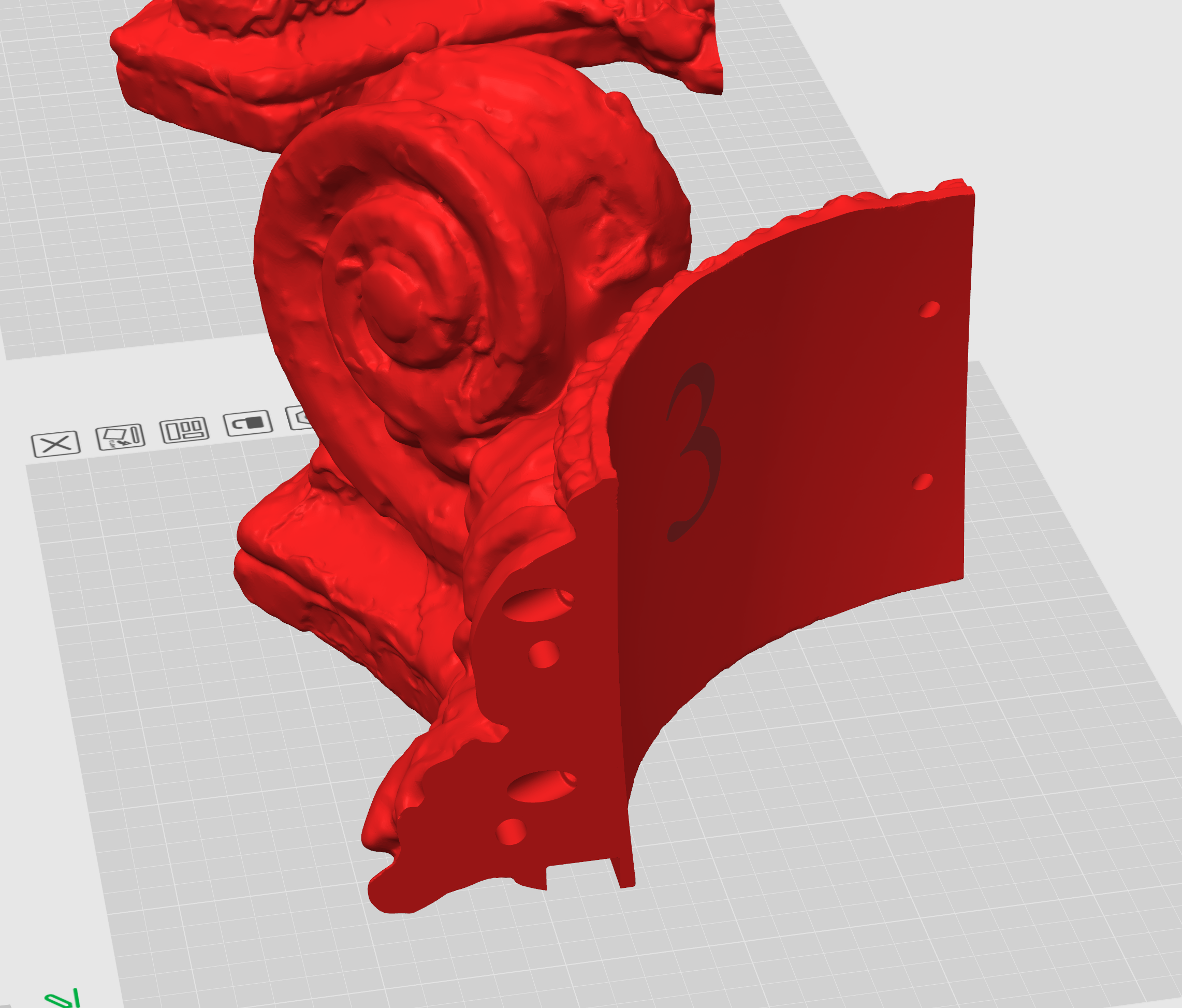

3. Engineering for the Build Plate

Because of the sheer size of these capitals, we couldn't print or install them in one piece. We segmented the model into four precise quadrants. Using Parametric Design, we integrated internal alignment tabs, interlocking joints, and recessed fastening points. This turned a decorative object into an engineered assembly.

4. The 3D Printing "Factory"

Each quadrant was printed on a Bambu H2D (high-speed, large-format printer). Multijet Fusion (MJF) or Selective Laser Sintering (SLS) would have also been good choices. Due to cost restrictions, we chose ABS (Acrylonitrile Butadiene Styrene) for its incredible durability, affordability, and resistance to Nashville’s heat and UV. Each column top consumed about 4kg (nearly 9lbs) of material, resulting in a dense, structural part that mimics the weight and "thud" of solid wood.

5. Post-Processing and Surface Prep

After the prints were finished, we removed the external support structures. To erase the "3D printed look" (layer lines), we media blast the parts. This not only smoothed the surface but gave the ABS a slightly porous texture similar to aged, painted timber, providing the perfect "tooth" for the primer to bond.

6. Installation: Seamless Integration

The quadrants were taken to the job site, where they were screwed, glued, and fastened around the top of the columns. Because we had designed the fasteners into the 3D model, the fit was airtight. A final coat of historic-palette paint tied the new and old together. The result? You can stand five feet away and wouldn't be able to tell which capitals were carved in 1910 and which were printed in 2025.

Why Nashville Architects are Making the Switch

For Historic Zoning Overlay projects, this workflow is a game-changer. It offers:

Historical Accuracy: Captures "weathering" that hand-carving can't replicate.

Symmetry: Every replacement part is a perfect clone of the master original.

Modern Durability: Unlike wood, 3D-printed ABS won't rot, warp, or fall victim to termites.

Ready to Restore Your Piece of Nashville?

Whether it's a porch in Edgefield or a cornice in Franklin, don't let history fade away. We can scan it, archive it, manufacture it, and preserve it for the next century.