Reviving Nashville’s Grandeur: How 3D Scanning and Artisan Craftsmanship Save Local History

Nashville isn't just the Music City; it’s a city of stories etched into brick, stone, and—most delicately—ornamental plaster. As our neighborhoods evolve, from the historic manors of Belle Meade to the Victorian charms of East Nashville, the challenge of architectural preservation becomes more technical.

When a piece of history crumbles, you can't just buy a replacement at a big-box store. You have to recreate it. We recently completed a restoration project involving the reproduction of intricate plaster crown molding, blending "old world" artistry with cutting-edge metrology.

Here is how we bridged a century of craftsmanship using 21st-century technology.

The Challenge: Beyond the "Off-the-Shelf" Fix

Standard molding profiles often fail to capture the scale and soul of Nashville’s historic builds. In this project, the original plaster had suffered significant water damage. To maintain the home's National Register of Historic Places integrity, we needed an exact match—not a "close enough" substitute.

The Process: From Photons to Plaster

1. Digital Preservation via Laser Scanning

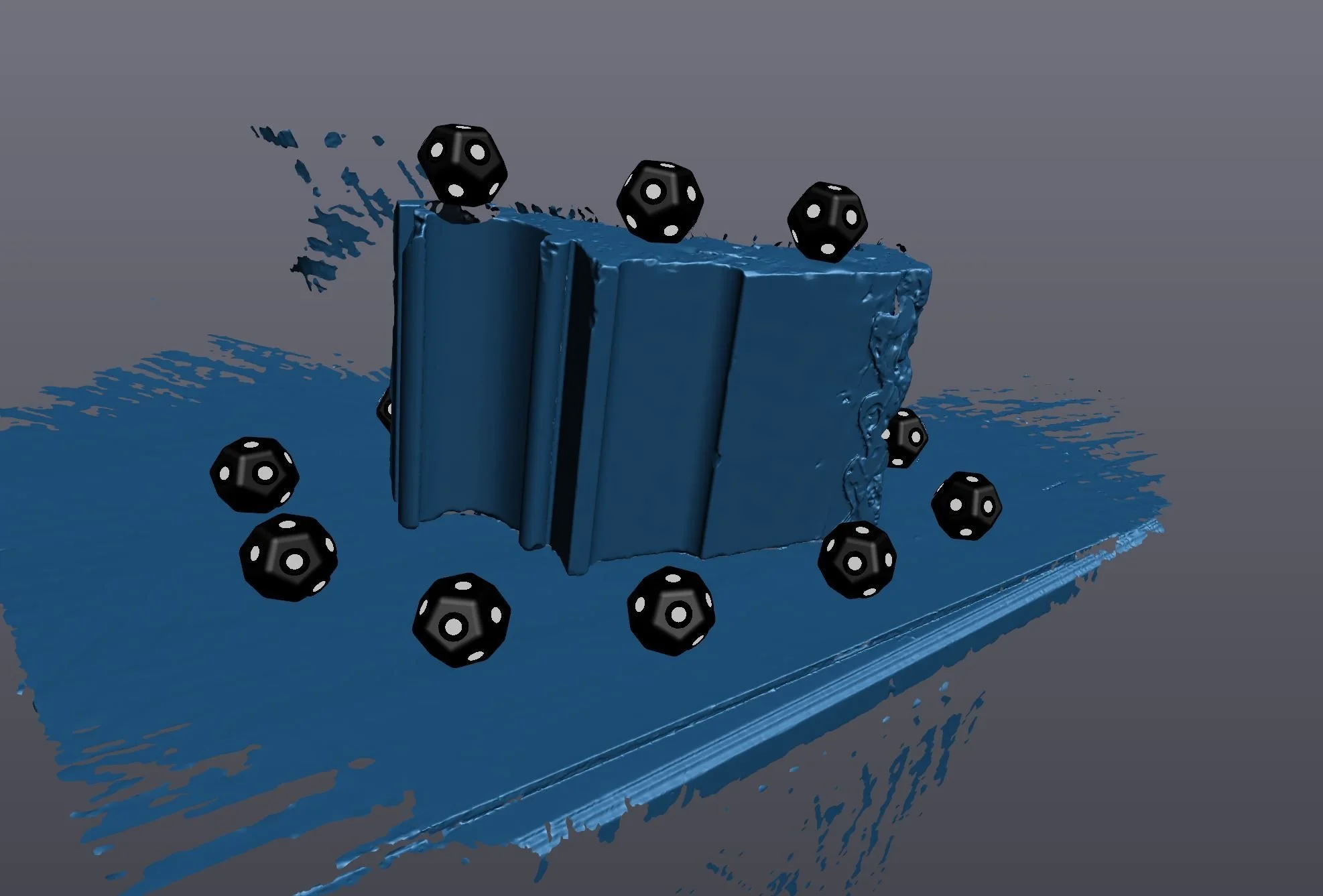

The process began by carefully removing a salvageable "master section" of the original trim. Instead of traditional physical templating, which can be messy and imprecise, we utilized 3D laser scanning. This allowed us to capture the exact geometry of the profile, including the subtle nuances created by craftsmen over a hundred years ago.

2. Refining the Digital Twin

Once we had our raw point cloud, we moved into the digital lab. Using Creaform’s VXElements, VXmodel, and Creaform OS software, we "cleaned" the scan data—removing dust, imperfections, and old paint that had obscured the original lines. We then extracted a hyper-accurate cross-section.

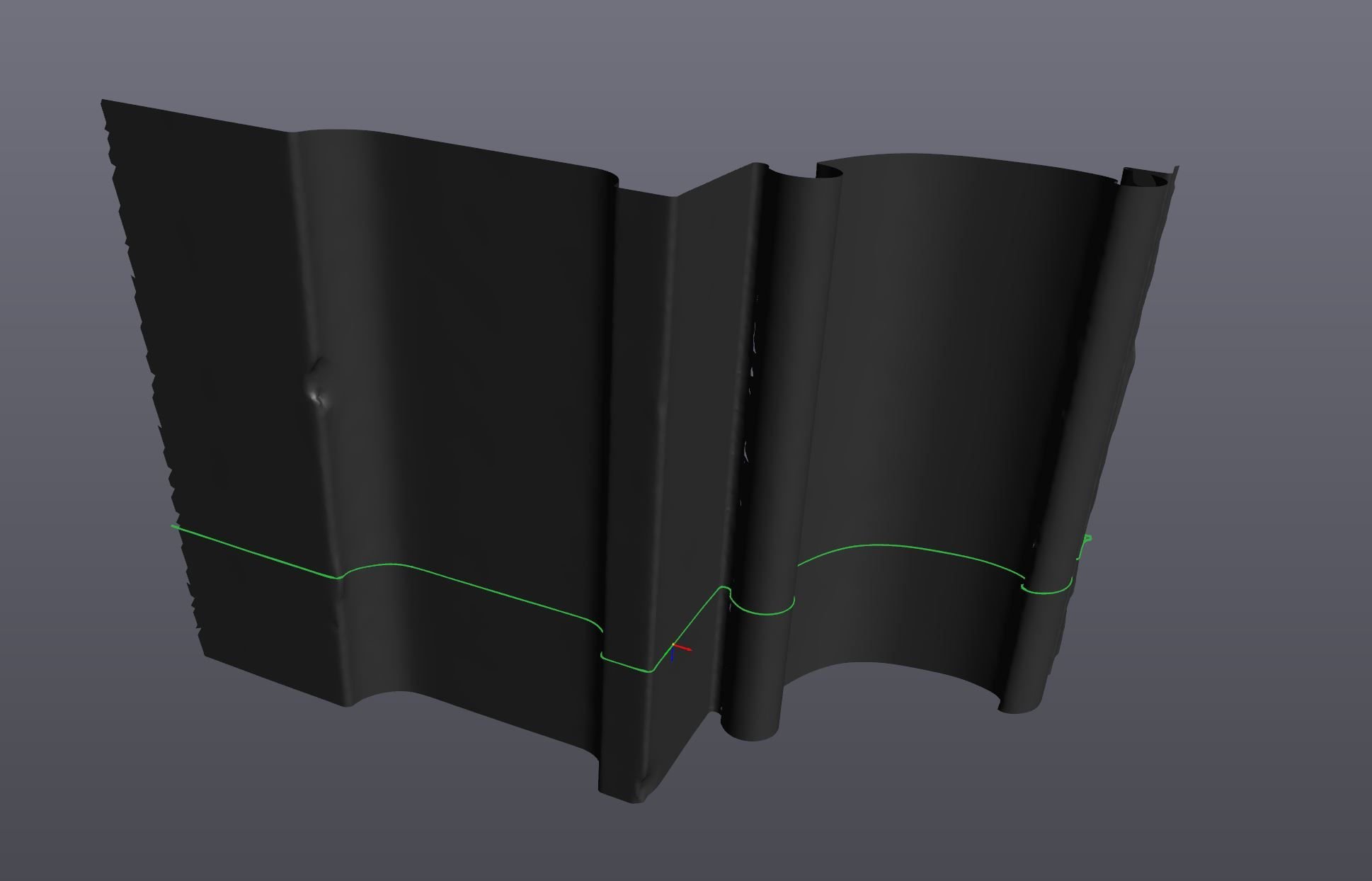

3. Engineering the Die in solidworks, vxmodel, and creaform os

To turn a digital line into a physical tool, we used our line drawing to create a DXF (Drawing Exchange Format). This stage is crucial for Mechanical Design; we adjusted the profile to ensure the resulting tool would produce a crisp, clean "pull" through the wet plaster.

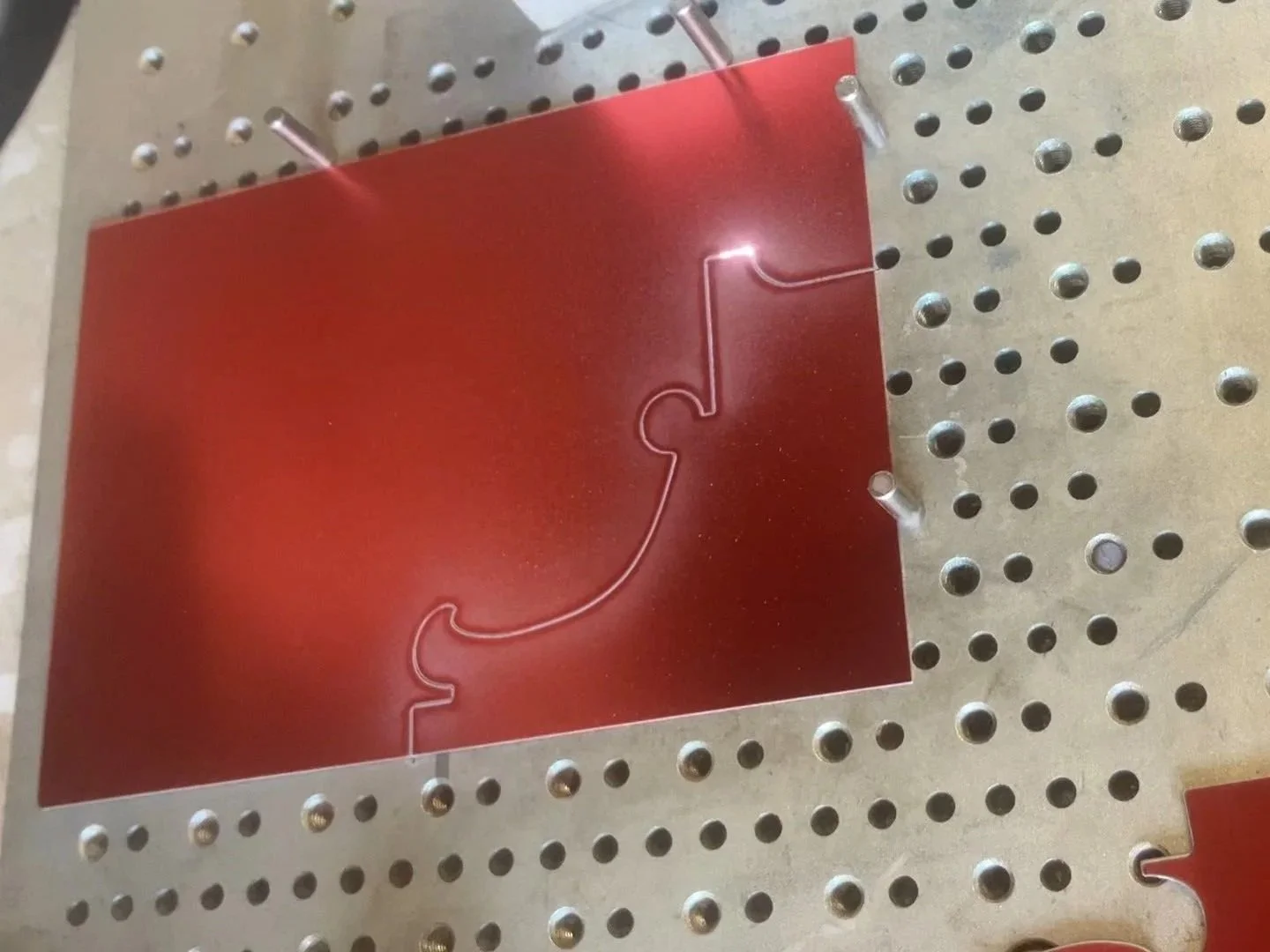

4. Precision Laser Cutting

Precision is nothing without power. We collaborated with local specialist Chris Henry at ACT Machine and Manufacturing, who used industrial-grade laser cutting and Autodesk Fusion to carve our refined profile into a durable aluminum die. This die (or "knife") serves as the negative image of the molding.

5. The Artisan’s Touch: "Running" the Plaster

Technology takes us 90% of the way, but the final 10% belongs to the hands of local plaster artisans. Using the custom-cut aluminum die, these craftsmen "ran" the new trim. By pulling the die over a bed of wet plaster, they created long, seamless lengths of crown molding that are identical to the 19th-century originals.

Why This Matters for Nashville Homeowners

Using a digital-to-analog workflow ensures that Nashville’s architectural DNA remains intact. Whether you are a developer working on a historic tax credit project or a homeowner restoring a family legacy, these modern techniques offer:

Unmatched Accuracy: No more "gaps" or mismatched corners.

Efficiency: Faster turnaround than hand-carving templates.

Durability: Aluminum dies provide more consistent results than traditional wood-and-tin versions.

Let’s Preserve Music City Together

Preservation is about more than just looking backward; it’s about using the best tools of today to honor the masterpieces of yesterday. If you’re ready to start your project, head over to the Scanning page to learn more and schedule a scanning session, or shoot us a message with your questions on our contact form!